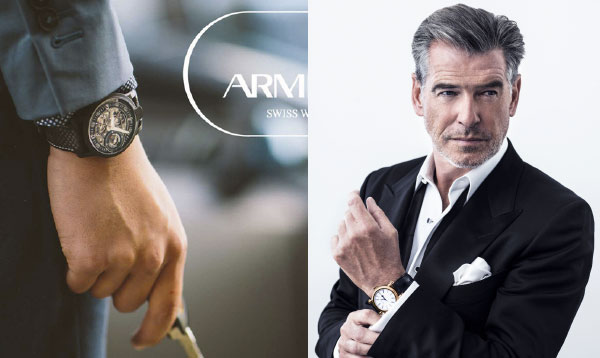

For Serge Michel, a native of Bern and entrepreneurial young owner of the Armin Strom brand, “a watch is judged by its heart”. It took both heart and courage to decide to invest in a Manufacture in 2008-2009, just as the world economic crisis was exploding. Daring does not necessarily go hand in hand with excess, because the three levels of this 400m2 production unit in Bienne accommodate a mere two dozen employees. Few brands can lhowever lay claim to similar assets. Five calibres have been developed by this small team of passionate people, ranging from an automatic movement to a double barrel tourbillon.

Size and talent also do not always go hand in hand, and the number of trades mastered in Armin Strom’s workshops is impressive. Over and above pure watchmaking, the construction and design are unmatched, as are the profile-turning and milling, cutting and hand engraving, decoration, galvanic plating and naturally the open-working that was the speciality of the brand’s eponymous founder – to such an extent that in 1990, the Guinness Book of Records registered the name Armin Strom in its pages as the smallest open-work watch made by hand (with a 12.5mm diameter).

This record is still in place. While it is undoubtedly more contemporary and adapted to suit the style of new products, openworking is still part of the brand DNA, as is evident in most of the seven collections, of which four are inspired by the four elements (air, water, fire and earth). Up till now, the technical prowess that Serge Michel finds the most noteworthy is the chassis of the power-reserve differential, mainly due to the complexity of being turned, milled and cut. In addition, the brand is now planning to increase its turning and milling capacity. Only the barrel springs and balance-springs along with the screws come from external suppliers. With solid foundations, titanic determination, a long-term vision and timepieces with a strong personality, Armin Strom continues its great adventure with unshakeable conviction.

Size and talent also do not always go hand in hand, and the number of trades mastered in Armin Strom’s workshops is impressive. Over and above pure watchmaking, the construction and design are unmatched, as are the profile-turning and milling, cutting and hand engraving, decoration, galvanic plating and naturally the open-working that was the speciality of the brand’s eponymous founder – to such an extent that in 1990, the Guinness Book of Records registered the name Armin Strom in its pages as the smallest open-work watch made by hand (with a 12.5mm diameter).

This record is still in place. While it is undoubtedly more contemporary and adapted to suit the style of new products, openworking is still part of the brand DNA, as is evident in most of the seven collections, of which four are inspired by the four elements (air, water, fire and earth). Up till now, the technical prowess that Serge Michel finds the most noteworthy is the chassis of the power-reserve differential, mainly due to the complexity of being turned, milled and cut. In addition, the brand is now planning to increase its turning and milling capacity. Only the barrel springs and balance-springs along with the screws come from external suppliers. With solid foundations, titanic determination, a long-term vision and timepieces with a strong personality, Armin Strom continues its great adventure with unshakeable conviction.