Amadeo® Fleurier BraveHeart®

Case : Amadeo® convertible in 18K white gold (92.39gr), red gold (89.18gr) or platinum 950/1000, chain in 18K white or red gold, water-resistant to 30m Diameter : 45.20mm Movement : hand-wound mechanical movement (Caliber 17BM02AI22J, 22 day power reserve), 722 components with hand decoration like chamfering and circular graining Functions : Hours, retrograde minutes, double coaxial seconds on tourbillon, power reserve indicator, reversed hand-fitting Dials : black or white polished lacquered with applied Roman numerals Bracelet : full-grain alligator with 18K red or white gold ardillon Limited edition of 30 timepieces in 18K red gold Limited edition of 30 timepieces in 18K white gold Limited edition of 20 timepieces in 950/1000 platinum

The first of these two faces seems to possess a single hand, even though it presents three indications. The hours hand, slightly off-centered on the upper part of the movement, is the only hand to cross the surface of the main dial. A triangular index traces the 160° of the minutes sector, and moves back every hour to resume counting. A second 120° sector acts as the seconds indicator. Here again, there are no hands, but the gently chamfered and polished ends of the three arms of the tourbillon-carriage bridge alternate every 20 seconds, totaling one minute for every revolution of the tourbillon.

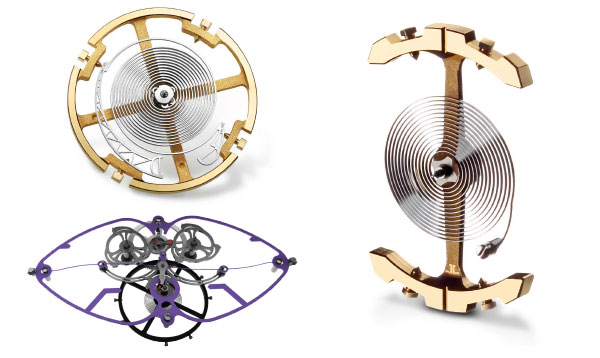

When the timepiece is turned over, another expression of time is revealed. Due to its innovative structure, the tourbillon presents a second, completely unprecedented face. We see the escapement as it has never been seen before : distinctly separated from the balance wheel and balance-spring, yet still perfectly connected to it. More surprisingly still, the seconds are also displayed on this side of the movement, on the axis of the tourbillon carriage. In addition to its features and the absolute symmetry of its indicator positions on either side of the movement, the patented reversed seconds add an extra touch of magic to the fascinating sight of the revolving tourbillon.

Driven by a desire for unequalled chronometry, owner Pascal Raffy included a colossal 22-day power reserve in the specifications of the Braveheart®, as the force supplied to a regulating organ is more constant over long periods of time. The two barrels that store this phenomenal energy each harbor a 104 cm-long spring, and take up half of the movement’s surface area. To keep the number of turns of a crown required to wind the movement reasonable, the technicians developed a patented spherical differential gear on the stem of the winding system that enables the gear ratio to be doubled.

Lightness and transparency have always been essential criteria for Bovet when developing and manufacturing movements regulated by a tourbillon. Their tourbillon carriages are also the subject of a specific patent, since none of the going-train wheels extend above the carriage, as is usually the case. To develop the Braveheart®, Bovet pushed back even further the boundaries imposed by this type of regulating organ while still improving the chronometry of the timepiece as a whole. The watchmakers came up with an innovative idea : to support the entire carriage in the middle of its axis. As well as halving the leverage force generated by the total height of the axis, this solution enabled the carriage’s weight to be spread over each side of its anchorage point. To achieve this, the escapement was positioned on the lower part of the axis, while the balance wheel and balance-spring occupied the upper section of the axis. This patented mechanism results in unequalled chronometry for a flying tourbillon, and creates an impression of a tourbillon levitating in the extra space provided by the three-quarter plates. The chronometric improvements obtained by the innovative architecture are compounded by those originating from a resolutely new balance wheel/balance-spring combination. As it has manufactured its own balance-springs since 2006, Bovet is one of the very few Houses capable of creating hair-springs, the component that requires the most rigorous knowledge and expertise of chemistry, physics and mechanics. Meanwhile, the verticality of this balance-spring led the technical department to design a three-armed tourbillon bridge. The entire tourbillon carriage is the subject of three patents.

Each of the 722 components of the movement passes through the expert hands of the artisans of this prestigious workshop, where all the traditional decorative techniques have been mastered to perfection. The decoration of the Braveheart®’s components often requires thirty times more time than that required to manufacture the same, functional component. Chamfering, circular graining… several techniques are used to enhance the precious mechanics of the Braveheart®, down to the rounding off of the curved arms of the tourbillon bridge, which alone requires two days of work and establishes a new landmark in the excellence of the decorative arts. As usual, the collector can also request any personalization he or she wishes.